-

market@legion.com.cn

Structure and Principle of Induction Heating Roller

1. What is induction heating roller?

The basic principle of induction heating roller is to provide alternating current to an induction coil, which could create magnetic flux. The effect of the magnetic flux induces electric current inside the roll shell, and creates heat by resistance (induction heating). The roll shell warms up by the current. This could minimize the energy loss and improve temperature accurate.

Since its appearance, induction heating roller has been widely used in the deep processing of various polymer materials, such as plastic sheet calender, fiber spinning processing, film lamination, drying of various materials, extension of inorganic materials, etc.

With the good performance of excellent temperature uniformity, environment friendly and low energy consumption, induction heating roller is the necessary equipment for the production of many advanced materials. The only deficiency of induction heating roller is the high cost, which restricts the application in many fields.

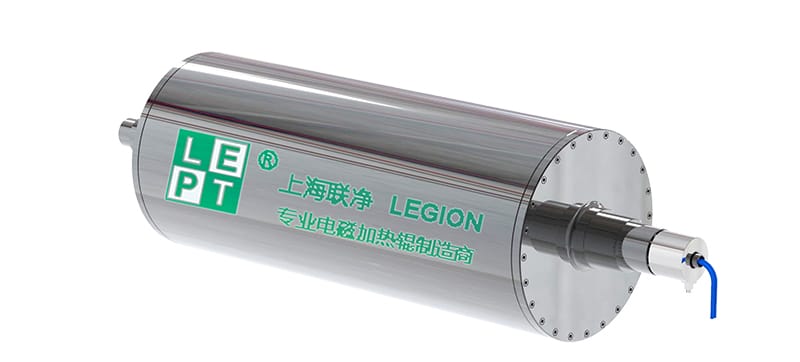

Outline drawing of tipical induction heating roller

2. Structure of induction heating roller

From the appearance, induction heating roller is divided into two types. One is named godet, which is used for the processing of synthetic fiber, carbon fiber, spandex, etc.

Tipical godet

The other type of roller is more common, with its roll shell supported by both ends.

Tipical induction heating roller

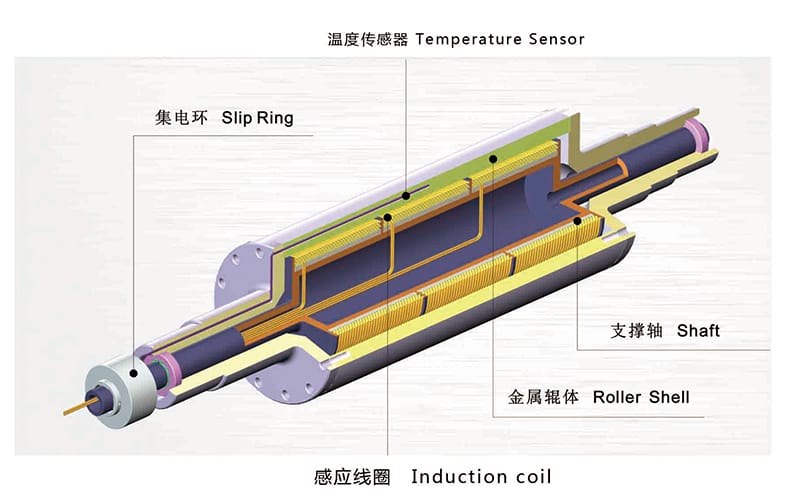

The internal structure of induction heating roller is composed of metal roller shell, shaft, induction coil, temperature sensor, slip ring, etc.

3. Advantages of induction heating roller

Wide temperature range

Roll shell is heated in electromagnetic field, with the temperature range in 50~420℃

High-precision temperature control, and uniform surface temperature distribution

Special energy distribution technology is employed in Legion induction heating roller, which ensures the uniform surface temperature within ±0.5℃;

Special temperature distribution can also be designed according to customer's requirement

Compact structure, space saving

Electricity is the only power source for Legion induction heating roller. So there is no need for additional facilities or special construction. The equipment requires minimal space and is easy to operate

Clean, and less maintenance operation

Without thermal oil, vapor or combustile material to leak, the work environment keeps clean and safe;

Friendly human-computer interaction screen, one button operation;

Communication protocol support: ModBus/TCP, ModBus RTU/ASCII RS-485, EtherNet-IP, etc.

Low energy consumption

Compared with thermal oil heating roller, energy consumption reduces about 50%, and over 70% in some industries

申明:如本站文章或转稿涉及版权等问题,请您及时联系本站,我们会尽快处理!